If you’re familiar with the Electric Eel Spinning Wheel, you might know that Maurice Ribble of Dreaming Robots, the mind behind the magic, recently released an electric cone winder!

I backed the project on Kickstarter in 2022. I have only backed three or four Kickstarter projects, but I have to say, Dreaming Robots was great about keeping backers in the know about the state of the project and allowing input. I forgot to fill out the address form when it came out, so my winder arrived in December, but that’s all on me! (Facepalm) I paid the Kickstarter backer price of $189 plus shipping. The cone winder now retails at $259 and is in stock as of the time of writing.

The winder was packaged securely and nothing was damaged in shipping. I opted for 10 cones with my winder.

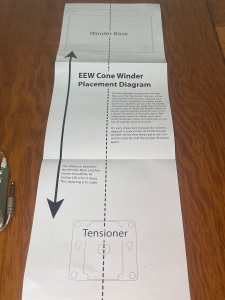

The manual is straightforward and comes with a template to show you how to lay out the tension unit and winder unit. I love that. I’m not great at eyeing measurements, and even though my blocking board lays things out by square inches, I can still measure things incorrectly. It’s a skill.

The cones are 27 grams according to my scale, and I like that they come in different colors. It’s fun. They look pretty cool on the inside once they hold yarn, too.

Assembly was straightforward and well laid out in the manual. There are excellent videos and written instructions on how to use the EEW Cone Winder on the Kickstarter page and FAQs on the product page. I avoided watching anything or reading anything but the initial Kickstarter campaign and the user manual before testing the winder for this post.

Initial Test-Winding Yarn from a Hank

I decided to cone up some of my friend Suzy’s yarn, Woolyboogers Felts. She works out of a studio next door to Get Stitchin’ and exclusively sells at craft shows and Get Stitchin’, so she’s just another great reason to stop by if you’re in the Tulsa area.

(You can sign up for one of my classes while you’re there! Standing classes the 2nd and 4th Wednesdays and Saturdays of the month!)

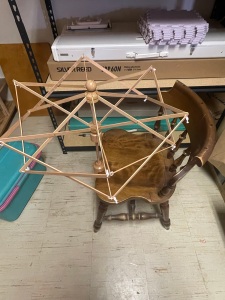

I used knitting machine clamps and the included tension unit clamp to hold the units in place on my counter, and I initially had my yarn swift (this thing) on the counter next to the winder. That meant the yarn was coming down from the swift to the counter level tension unit.

Using speeds 1 and 2 with the loosest, straight tension setting, I wound the 438 yards of sparkly goodness onto the cone. Well, the winder did all of the work. I supervised.

On the lowest settings and loosest tension, it took a few minutes to wind, but I wanted to be cautious learning the winder. I had a couple of issues with feeding into the tension unit from the swift when I had it sitting so much higher than the tension unit intake. It worked much better when I moved the swift to sit on a chair and the yarn intake was more level with the tension unit as it fed yarn in. The yarn winder had plenty of power to wind from the swift, but I found on the lowest tension it had to work a bit harder if the hank on the swift was held too tightly or the yarn was caught underneath itself.

After the slow speed test run with Woolyboogers, I decided to cone up four skeins of Berroco Modern Cotton DK. (I’ll be reviewing it soon, so be on the lookout for that post in the future!)

I wound each skein at a higher speed than the last, with the final at speed setting #5. I was catching a breeze from the swift at that point! I used the higher tension winding setup as shown in the manual for this yarn.

It looks great coned up! The cone has two small holes at the top for you to attach the yarn label and then store in the center of the cone.

I prefer a more tightly wound cone of yarn, especially for fibers like cotton. The looser tension setting is probably more ideal for delicate yarns. I didn’t experience any yarn breakage, and I did “jam” the winder a couple times. More on that in a bit.

Turn up your audio to hear what the EEW Cone Winder sounds like at speed #5 in my Instagram video below. My pictured setup isn’t ideal, but what I had worked just fine!

I wouldn’t say the cone winder is loud, but it definitely isn’t silent. You can hear it working rhythmically, but I didn’t find it unpleasant.

If you’ve wound a lot of yarn into cakes before, you’ll appreciate the electric cone winder doing the hard work for you. Your arms can get tired after a thousand yards, but with the winder, you’re just turning a dial after a little yarn threading. Easy peasy!

Experimenting and User Error

Ah, the aforementioned jam.

The only issues I ran into using the electric cone winder stemmed from user error and experimentation with yarn swift placement for intake through the tension unit.

At one point, I was pulling additional yarn lengths from the swift because the winder seemed to struggle with pulling directly from the swift.

I shouldn’t have been pulling additional yarn out. The winder didn’t need my help. It operated fine, albeit slowly, when I stopped feeding it yarn myself at low settings as well as after I increased the speed dial setting.

While I was pulling that additional yarn from the swift, knots and loops developed in the yarn and happened to hook themselves around the metal guide spiral. The winder kept going for a tiny bit (of course, it is set to ON and rotating) BUT then it stopped.

When I read the FAQs on the product page, I found the motor stopping is by design, and I appreciate that it stopped and didn’t break my yarn!

This is by design. It is bad for the motor to continue trying to spin when it is not spinning. At low power this can happen when it’s trying to spin slowly but there isn’t enough motor to actually spin the drum. In this case the motor will turn itself off until it sees no attempts to spin for 3 seconds. To work around this turn the speed dial to off and then wait three seconds and it will resume normal operations.

from the FAQs at https://www.dreamingrobots.com/eew-cone-winder/

This is one of the reasons why you don’t set the winder and leave it. If something happens, that delay gives you time to fix things.

I’ll say it again: winder does have enough power to be able to pull yarn off of a swift through the tensioner unit, but at low speed settings with looser tension it seemed more likely to knot up or loop around the metal guide spirals on the tension unit, especially if the yarn wasn’t feeding in quite even with the tension unit (that pesky user messing with it…). It may seem counterintuitive, but I didn’t experience the same looping when I upped the tension and the winder speed (and left well enough alone). Pulling extra yarn from the swift to feed into the tension unit just gave the yarn opportunities to form knots and loops and catch on the tensioner.

Yarn placement is important, and getting it right makes your experience with the cone winder much smoother.

Why Buy a Cone Winder

As someone with hand and arm issues, I am so excited to have a way to wind that doesn’t depend on my arms functioning well that day. And, since cones are the most ideal yarn put-up for machine knitting, I can say goodbye to my awkward cake yarn winder. It served me well, but I’m happy to move on, and I won’t miss the occasional loops across the top and bottom that sent my yarn rolling.

At $259, the electric eel cone winder is not cheap. That’s a chunk of change for anyone, but if you want to use hand knitting yarns by machine and your ball winder isn’t cutting it, I think it’s worth the investment, especially if you have years of knitting in front of you, or if you are like me and have issues with your hands, wrists, and arms in general. Cutting out the winding motion lets me use my body’s limited energy to work on actual knitting.

All opinions are honest and my own. Purchases are made with my own money. Links may be affiliate links. If you choose to purchase something using my Amazon affiliate link, I may earn a small commission at no cost to you. If you don’t have somewhere local to purchase your machine knitting needs, please consider using my links to support the site!

Thank you for joining me on my machine knitting journey! How do you prepare your yarn for machine knitting? Will you invest in a cone winder? Let me know in the comments!